Your cart is empty.

Q. How long have you been blowing glass for?

A. I've been blowing glass for 18 years. I started with stained glass and took some classes at college, then moving into small flame working while exploring a variety of classes.

Q. What's your favorite part of the process?

A. Just being able to create. Really enjoy creating new pieces and the whole design process.

Q. So what are some of you favorite artists or influences you have from the glass industry?

A. I'm definitely influenced by the Italians, the Venetians,

Emilio Santini - Flame Worker

Lucio Bubacco - Sculptor, Flame Worker

Robert Mickelson - American Flame Worker

Q. What is one of your favorite pieces you've seen?

Well, other than the new stratosphere pieces, that have the spinny sections inside, I've always loved a large banjo piece.

Q. What separates American glass from cheaper, lesser quality glass?

A. To begin with, the glass/product we use is a lot better quality and the time and love we put into each piece. This equates to a higher quality piece overall. China glass is about quantity over quality. My focus is to put out a quality piece every time. Some differences include quality of material, size and functionality.

Sometimes they take something we've designed that we know works, and begin tweaking it to make it their way, hence losing some of the functionality that we put into it. The strength of the product is far less. Seals are of less quality, and their annealing process which is at the end of the piece when it's finished, where it sits in a hot kiln for hours at high temperature and then slowly cools down which makes the glass stronger. The cheaper glass doesn't put the same amount of time into this process.

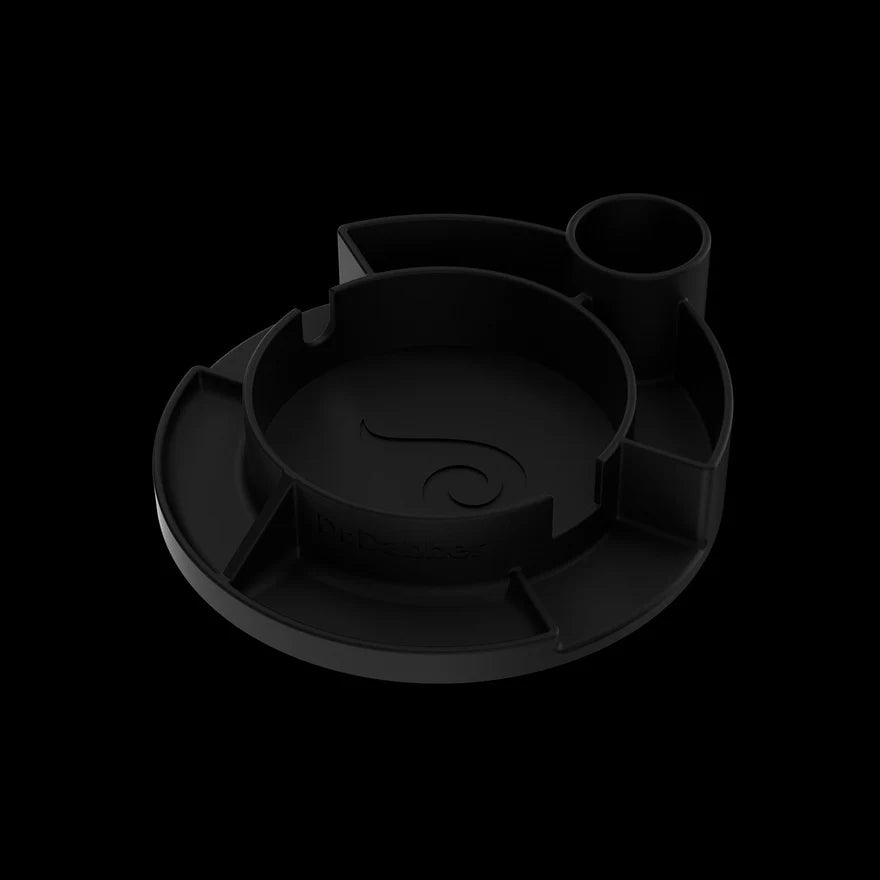

Q. Could you tell us a little about the pieces you make for Dr. Dabber?

A. I met Dr. Dabber many years ago and fell in love with their vape pens first, and Dr. Dabber has always been a pioneer in keeping the new products out there which is a great way to approach your company. I love being a part of Dr. Dabber and making these glass pieces for them.

Q. Tell us a little bit about the learning experience?

A. I first discovered glass when I was younger, my mother would collect clear glass, so would always have that around. In college is Missoula, Montana I discovered a stained glass class, and from there I discovered flame working, Italian glass, small beads, and then from there found others routes to do glass such as the hot shop, cast glass, fused glass. I moved to Eugene, Oregon and studied under a few guys out there who have all since retired. I moved to Corning, New York where the Corning Glass Studio, as well as the Corning Glass museum, are. I took as many classes as I could from many different artists, such as Robert Mickleson, Emilio Santini, and one of my favorite hotshot people to work with was George Kennard who blew amazingly large glass. I was able to learn a lot along the way from a variety of artists and looked for new ways to create a variety of glass pieces.